25

Aug

Power Tool Dust Extraction: Are You Using the Right Filter Class?

Health and safety is key within the construction industry. There are numerous hazards in this type of work, and employees’ personal health and safety can often be at serious risk.

One of the main hazards that workers face is construction dust created by power tools. Exposure to this type of dust can be controlled effectively via on-tool extraction, which removes and captures the dust as it is produced.

In this post, we have summarised everything you need to know about power tool dust extraction! We explain the different dust extractor filter classes and clarify which one you should be using as recommended by the Health and Safety Executive (HSE).

So, if you want to maintain a safe work environment and ensure that you are meeting legal requirements, then read on!

A lot of construction jobs create high levels of dust, especially when operating power tools like saws, sanders, breakers, etc. Regularly breathing in construction dust can seriously damage your health and cause diseases like lung cancer, emphysema, chronic obstructive pulmonary disease (COPD) and silicosis (silica is the second biggest killer of construction workers after asbestos).

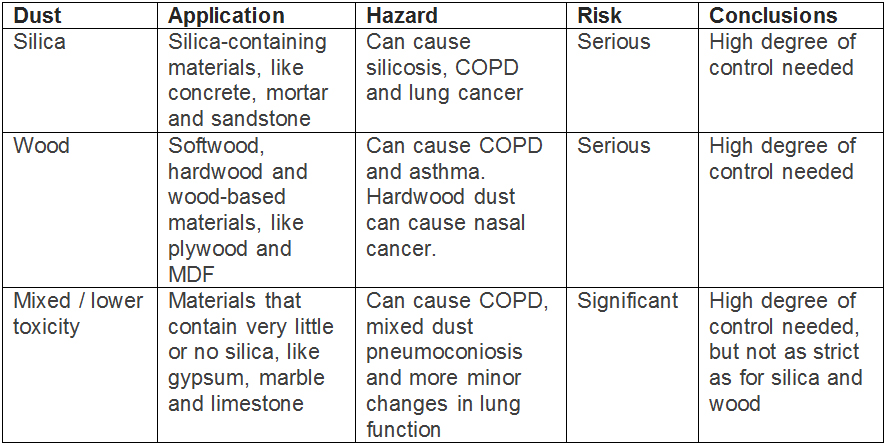

Generally, there are three main types of dust found on construction sites:

One of the most effective ways to control exposure to construction dust is on-tool extraction. This involves fitting a local exhaust ventilation (LEV) system directly on to a power tool to extract and capture any dust that it produces.

One of the most effective ways to control exposure to construction dust is on-tool extraction. This involves fitting a local exhaust ventilation (LEV) system directly on to a power tool to extract and capture any dust that it produces.

A LEV system is comprised of numerous individual parts:

The Health and Safety at Work etc. Act 1974 requires employers (including those who are self-employed) to “ensure, so far as is reasonably practicable, the health, safety and welfare at work” of their employees and anyone else who may be affected by their activities.

The Control of Substances Hazardous to Health Regulations 2002 (COSHH) also requires employers to prevent workers from being exposed to substances that are hazardous to their health. If this is not feasible, then exposure must be adequately controlled.

Power tools pose a much higher health risk than manual tools as they produce a lot more dust. In order to provide adequate control for employees, COSHH requires the cost and effort of supplying power tool dust extraction to be proportionate to the health risk. The higher the risk; the higher the standard of extraction needed.

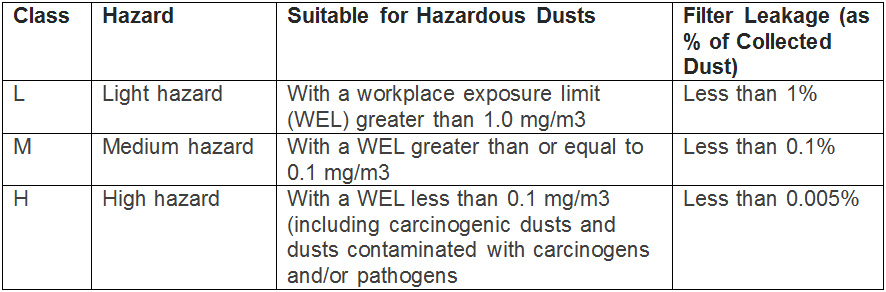

To cater to these different standards, dust extractors have different filter classes. These filter classes establish performance limits for the maximum amount of particular hazardous dusts that can penetrate through the filter back into the work environment:

As illustrated in the table above, class M and H units are designed for higher hazard dusts which pose a more serious health risk. The HSE proposes that a minimum of a class M unit is used as part of on-tool LEV systems for silica and wood dust in the workplace. A minimum of a class L unit should be used for mixed/lower toxicity dusts.

Are you using the right filter class?

Failure to comply with these recommendations can lead to enforcement by the HSE, including appropriate legal action.

As mentioned above, your dust extractor should be suitable for the dust type of the material(s) that you will be working with. For example, if you are sawing wood on site, your dust extraction system should be a minimum class M unit.

As mentioned above, your dust extractor should be suitable for the dust type of the material(s) that you will be working with. For example, if you are sawing wood on site, your dust extraction system should be a minimum class M unit.

There are numerous other factors that should also be taken into account, such as:

Most power tool manufacturers sell complete dust extraction systems for use with their machines. However some parts, like extraction units, can be used with other tool brands and models. To ensure the best level of dust control, it is crucial that you choose parts that are compatible and work well not only together, but with the tool also.

Here at Kelvin Power Tools, we stock a great range of L and M class dust extractors from the best trade brands, including Bosch, Festool and Metabo.

In order to effectively control dust risks, your LEV system must be operated properly. You should receive instructions from the manufacturer(s) of your dust extraction system regarding how to do this. Not all systems operate in the same way, so make sure you follow the specific instructions for your equipment carefully.

In order to effectively control dust risks, your LEV system must be operated properly. You should receive instructions from the manufacturer(s) of your dust extraction system regarding how to do this. Not all systems operate in the same way, so make sure you follow the specific instructions for your equipment carefully.

Before operating your dust extraction system, you should be adequately informed/trained on how to:

To achieve the best level of dust control, your LEV system needs to be properly maintained. You should receive instructions from the manufacturer(s) of your dust extraction system explaining how to do this. Not all systems will require the same level of maintenance, so make sure you follow the specific instructions for your equipment carefully.

To achieve the best level of dust control, your LEV system needs to be properly maintained. You should receive instructions from the manufacturer(s) of your dust extraction system explaining how to do this. Not all systems will require the same level of maintenance, so make sure you follow the specific instructions for your equipment carefully.

Ensure that your dust extractor works properly the first time, every time. If it doesn’t, then a formal maintenance check should be conducted to source the issue.

Formal maintenance checks should be conducted on your extraction system at least once a week. You might have to do this more often if there is a high risk of the equipment being damaged.

Some common maintenance issues that you might encounter are:

Proper servicing and testing should also be conducted on your LEV system for a more thorough examination. This will ensure that the equipment can continue to perform as intended. PAT testing is the most efficient way to do this. Full details regarding PAT testing can be found on our website here.

We hope that we have helped you understand the ins and outs of power tool dust extraction a bit better. Maintaining a safe work environment is crucial within the construction industry and LEV systems are a great contribution towards this!

It is crucial that your dust extractor has the correct filter class as recommended by the HSE, as this will provide the best level of dust control and allow you to meet legal requirements.

It is also important that you are operating and maintaining the dust extraction system correctly to ensure optimum performance.

Tags: dust, dust extraction, dust extractor, extraction, extractor

Get the latest news, special offers and up-coming events from Kelvin Power Tools delivered direct to your inbox.

Our website uses cookies so that we can provide a better service. Continue to use the site as normal if you're happy with this, or find out how to manage cookies.